Taconic RF-60TC High-Frequency PCB – DK 6.15 with 10mil, 20mil, 30mil, and 60mil Thickness, Coated with Immersion Gold, Tin, HASL, and OSP

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Experience Superior Performance with Taconic RF-60TC High-Frequency PCBs

Elevate your high-frequency PCB designs with Taconic RF-60TC laminates, engineered for high-power RF and microwave applications. Featuring a ceramic-filled PTFE (Polytetrafluoroethylene) laminate with a fiberglass substrate, RF-60TC delivers a dielectric constant (Dk) of 6.15, ensuring exceptional thermal management, low insertion loss, and enhanced antenna gain.

Designed to operate at lower temperatures and with improved dimensional stability, RF-60TC is perfect for miniaturized antennas, high-power amplifiers, and satellite applications. Its low coefficient of thermal expansion (CTE) and reliable plated through holes (PTH) make it ideal for multilayer PCB designs.

Key Features of Taconic RF-60TC Laminates

1.Advanced Material Composition: Ceramic-filled PTFE with fiberglass substrate for superior performance.

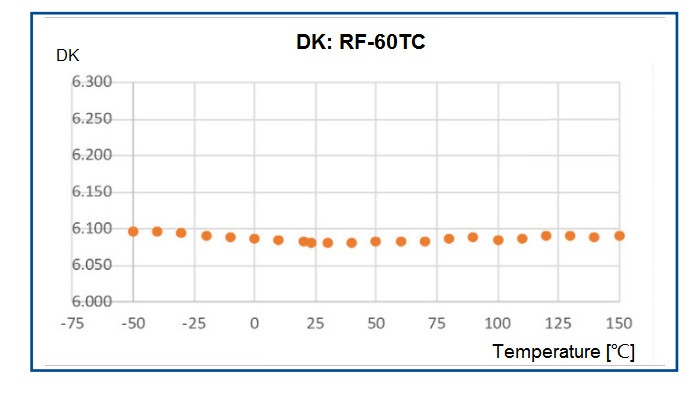

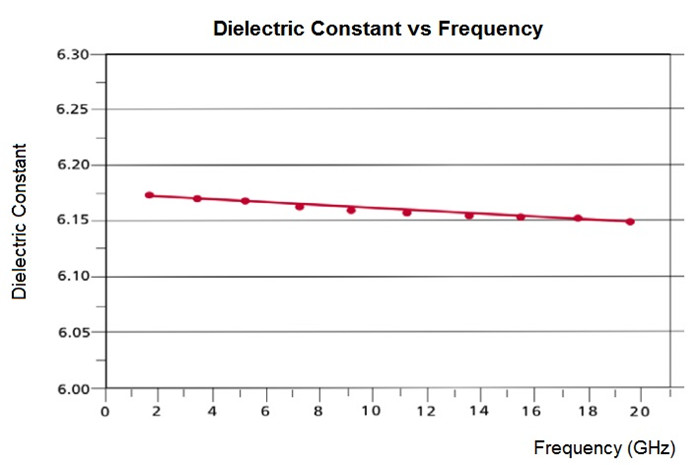

2.Optimized Dielectric Constant (Dk): 6.15 ± 0.15 at 10 GHz, ensuring consistent signal integrity.

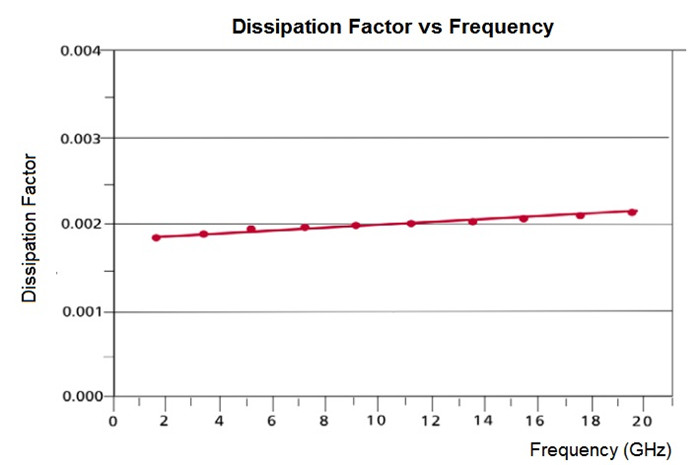

3.Low Dissipation Factor (Df): 0.002 at 10 GHz, minimizing signal loss.

4.High Thermal Conductivity: Exceptional heat dissipation for high-power applications.

5.Low Z-Axis CTE: Ensures reliability in multilayer PCB designs.

6.Low Moisture Absorption: 0.03%, ensuring stability in various environments.

7.Flame Retardant: Meets UL 94 V-0 requirements for safety and compliance.

.jpg)

Why Choose Taconic RF-60TC Laminates?

Improved Loss Tangent: Lower insertion loss and enhanced antenna efficiency.

High Thermal Conductivity: Reduces operating temperatures and extends component life.

Enhanced Dimensional Stability: Ensures reliable performance in multilayer PCBs.

Low Z-Axis CTE: Ideal for reliable plated through holes (PTH).

Excellent Adhesion to Metal: Available in lower profile and heavy metal backing options.

Stable Dk Over Frequency and Temperature: Ensures consistent performance across various conditions.

Applications of Taconic RF-60TC Laminates

High-Power Amplifiers

Miniaturized Antennas (GPS, PATCH, RFID Reader)

Filters, Couplers, and Dividers

Satellite Communications

.jpg)

Our PCB Capability (RF-60TC)

PCB Capability (RF-60TC) |

|

PCB Material: |

PTFE based, ceramic filled fiberglass |

Designation: |

RF-60TC |

Dielectric constant: |

6.15± 0.15 @10 GHz |

Dissipation factor: |

0.002 @10 GHz |

Layer count: |

Single Layer, Double Layer, Multilayer, Hybrid PCB |

Copper weight: |

1oz (35 µm), 2oz (70µm) |

PCB thickness: |

5mil (0.127mm), 10mil (0.254mm); 20mil (0.508mm), 25mil(0.635mm); 30mil (0.762mm), 60mil (1.524mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, ENEPIG, OSP, Pure gold etc.. |

Upgrade Your High-Frequency PCB Designs with Taconic RF-60TC!

Whether you're working on high-power amplifiers, miniaturized antennas, or satellite communications, Taconic RF-60TC laminates offer the perfect combination of performance, reliability, and thermal management. With low insertion loss, high thermal conductivity, and stable Dk over frequency and temperature, RF-60TC is the ideal choice for your next high-frequency PCB project.

Typical Values of RF-60TC

RF-60TC Typical Values |

|||||

Property |

Test Method |

Unit |

Value |

Unit |

Value |

Dk @ 10 GHz |

IPC-650 2.5.5.5.1 (Modified) |

|

6.15 ± 0.15 |

|

6.15 ± 0.15 |

Df @ 10 GHz |

IPC-650 2.5.5.5.1 (Modified) |

|

0.002 |

|

0.002 |

TcK |

|

ppm/°C |

-3.581 |

ppm/°C |

-3.581 |

Dielectric Breakdown |

IPC-650 2.5.6 |

kV |

55 |

kV |

55 |

Dielectric Strength |

IPC-650 2.5.6.2 |

V/mil |

550 |

V/mm |

21,654 |

Arc Resistance |

IPC-650 2.5.1 |

Seconds |

>180 |

Seconds |

>180 |

Moisture Absorption |

IPC-650 2.6.2.1 |

% |

0.03 |

% |

0.03 |

Flexural Strength (MD) |

IPC-650 2.4.4 |

psi |

10,000 |

N/mm2 |

69 |

Flexural Strength (CD) |

IPC-650 2.4.4 |

psi |

9,000 |

N/mm2 |

62 |

Tensile Strength (MD) |

IPC-650 2.4.19 |

psi |

9,000 |

N/mm2 |

62 |

Tensile Strength (CD) |

IPC-650 2.4.19 |

psi |

7,000 |

N/mm2 |

48 |

Young’s Modulus (MD) |

ASTM D 3039/IPC-TM-650 2.4.19 |

kpsi |

721 |

N/mm2 |

4971 |

Poisson’s Ratio (MD) |

ASTM D 3039/IPC-TM-650 2.4.19 |

|

0.155 |

|

0.155 |

Peel Strength (1 oz. ED) |

IPC-650 2.4.8 |

lbs/in |

8 |

N/mm |

1.43 |

Thermal Conductivity (Unclad) |

IPC-650 2.4.50 |

W/M*K |

0.9 |

W/M*K |

0.9 |

Thermal Conductivity (CH/CH) |

IPC-650 2.4.50 |

W/M*K |

1 |

W/M*K |

1 |

Thermal Conductivity (C1/C1) |

IPC-650 2.4.50 |

W/M*K |

1.05 |

W/M*K |

1.05 |

Dimensional Stability (MD) |

IPC-650 2.4.39 Sec. 5.4 (After Bake) |

mils/in |

0.01 |

mm/M |

0.01 |

Dimensional Stability (CD) |

IPC-650 2.4.39 Sec. 5.4 (After Bake) |

mils/in |

0.69 |

mm/M |

0.69 |

Dimensional Stability (MD) |

IPC-650 2.4.39 Sec. 5.5 (Thermal Stress) |

mils/in |

0.06 |

mm/M |

0.06 |

Dimensional Stability (CD) |

IPC-650 2.4.39 Sec. 5.5 (Thermal Stress) |

mils/in |

0.8 |

mm/M |

0.8 |

Surface Resistivity |

IPC-650 2.5.17.1 (After Humidity) |

Mohm |

1.0 x 108 |

Mohm |

1.0 x 108 |

Volume Resistivity |

IPC-650 2.5.17.1 (After Humidity) |

Mohm/cm |

1.0 x 108 |

Mohm/cm |

1.0 x 108 |

CTE (X, Y axis) |

IPC-650 2.4.41 (RT- 150 °C) |

ppm/°C |

9.9 |

ppm/°C |

9.9 |

CTE (Z axis) |

IPC-650 2.4.41 (RT- 150 °C) |

ppm/°C |

40 |

ppm/°C |

40 |

Density (Specific Gravity) |

IPC-650 2.3.5 |

g/cm3 |

2.84 |

g/cm3 |

2.84 |

Specific Heat |

IPC-650 2.4.50 |

J/gK |

0.94 |

J/gK |

0.94 |

Td (2% Wt. Loss) |

IPC - 650 2.4.24.6 / TGA |

°F |

930 |

°C |

500 |

Td (5% Wt. Loss) |

IPC - 650 2.4.24.6 / TGA |

°F |

960 |

°C |

515 |

Flammability Rating |

UL 94 |

|

V-0 |

|

V-0 |